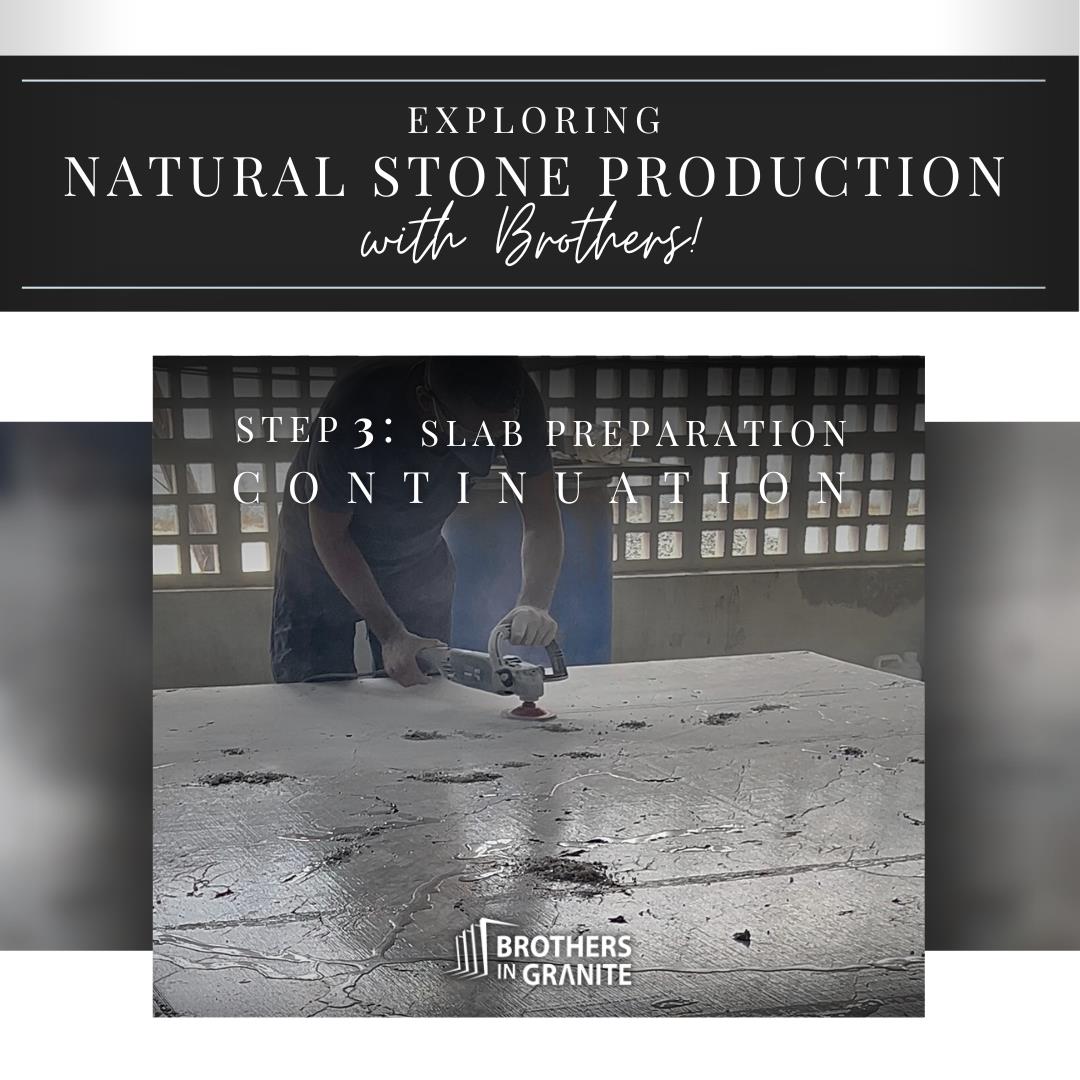

Blog Let’s continuing our journey of Step 3: Slab Preparation!

04/05/2024

Let’s continuing our journey of Step 3: Slab Preparation!

Anyone who has spent time in nature or collected a pretty rock on a walk knows that stone as it exists in the ground is far from the perfectly polished slabs that arrive in our shops and homes. In fact it takes a huge amount of work to reach this point and in the next step of our slab production education series we want to show you the steps we take to ensure you get the most beautiful natural stone possible for your designs.

We’ve shown previously how blocks are selected, cut, and protective mesh is installed. The next step involves the actual finishing of the face of the material. The first step involves filling all the natural holes, voids, and fissures in the stone. These are present in all materials we cut and “fixing” them is an integral part of stone production. Brothers in Granite use a mixture of pulverized stone from the same block to match color along with epoxy resins for strength and shine. The epoxy we use is actually stronger than the natural stone it protects and will ensure your finished products look great for years to come.

Once this resin is applied the slabs are protected and left to dry before heading to the next important step, making the slabs suitable for polishing. In this step we polish down any imperfections or raised surfaces leftover from the previous stage and the surface is made smooth enough to proceed to the next step - our polishing line!

Step 3: Slab Preparation

Ready for a behind-the-scenes look at stone refinement? Watch our video to see stone transformation!