Blog Production Sneak Peak - Sealing Quartzites!

09/27/2024

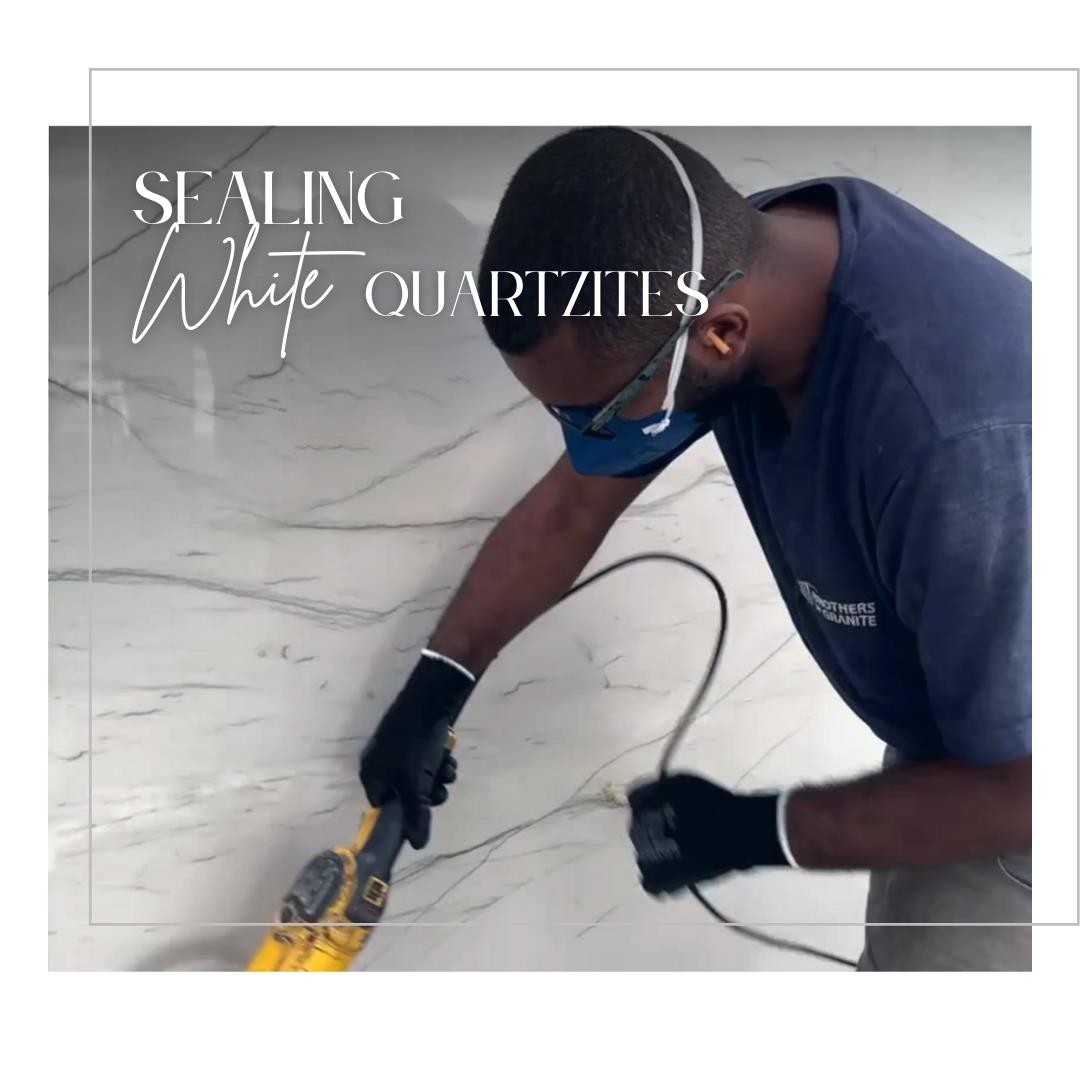

At Brothers in Granite, despite our name, quartzites are a huge part of what we do. We field natural stone questions every day and one of the most common from fabricators is how to avoid water absorption in some of our “sandy” white quartzites such as Bianco Superiore and Mont Blanc.

Because of the way they’re formed, as a kind of intermediate step between sandstone and quartzite, these materials can have a large amount of pore space that can act as a sponge to soak up moisture.

Because of the way they’re formed, as a kind of intermediate step between sandstone and quartzite, these materials can have a large amount of pore space that can act as a sponge to soak up moisture.

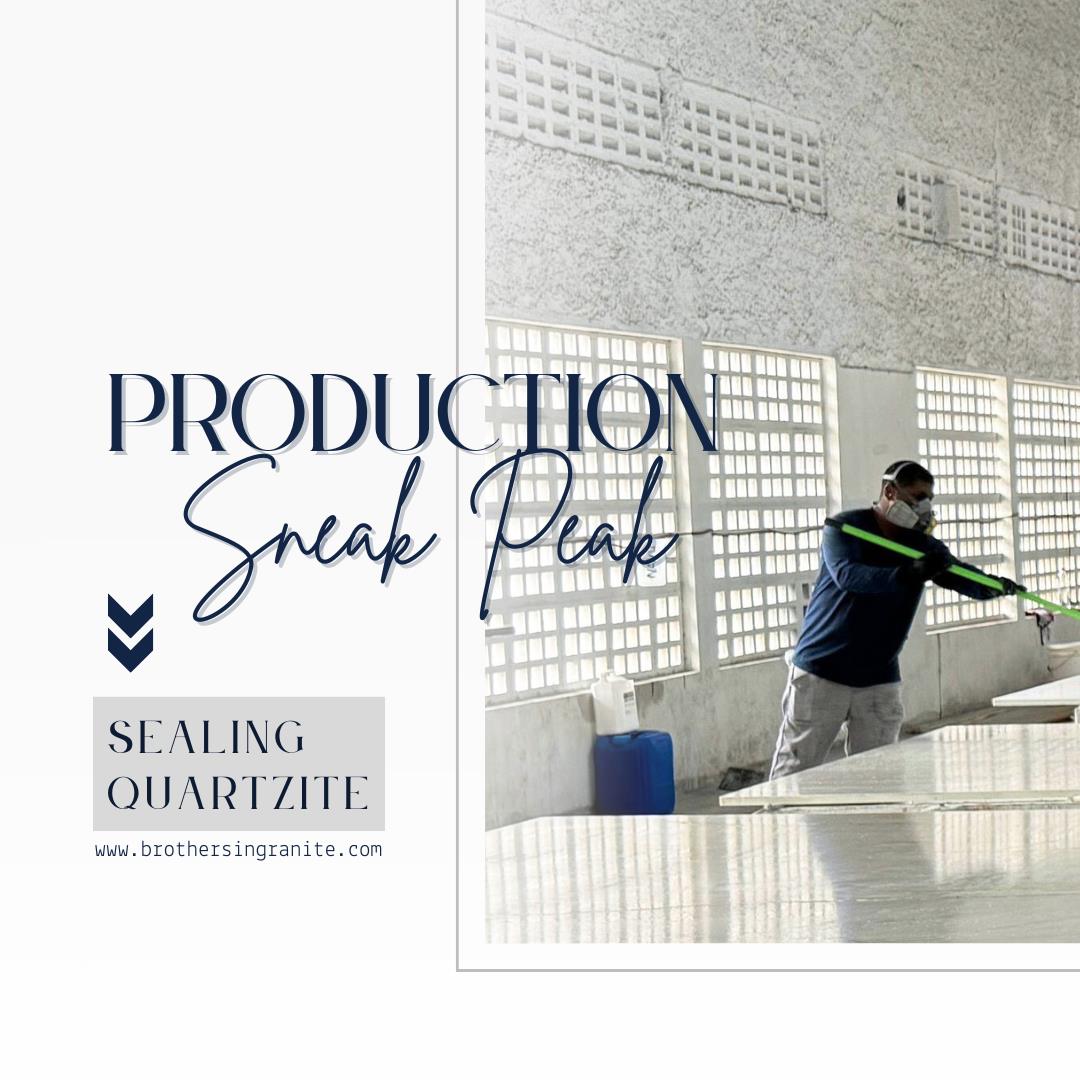

What can we do to help? In this video one of our owners, Daniel, shows how we apply a layer of sealer at our factory as the final step in our production process. Along with the resin applied to the back, this leaves little room for moisture to enter the slab during transport. Its important to note that cut edges will still need to be sealed after fabrication and its vital that the slabs be completely dry before this step is completed.

It’s still possible that problems will arise with the materials but if so, we’re only a phone call or email away and we’re always happy to help with suggestions or best practices. Demand for white quartzites continues to rise here and learning to comfortably work with them is a win for your business.

See our current stock of sealed white quartzites protected against moisture at store.brothersingranite.com!

It’s still possible that problems will arise with the materials but if so, we’re only a phone call or email away and we’re always happy to help with suggestions or best practices. Demand for white quartzites continues to rise here and learning to comfortably work with them is a win for your business.

See our current stock of sealed white quartzites protected against moisture at store.brothersingranite.com!